JML SALES, INC. - We Are Precision Production Grinding, Production Machining, and Production Deburring Manufacturers' Representatives

Our Job Is Helping You Achieve Your Goals!

Grinding Equipment

Grinding Wheels

Deburring Equipment

Deburr Brushes

Coolant Filtration

Coolants

PCD & PCBN Cutting Tools

Diamond Dressing Tools

Rotary Diamond Dressers

Engineered Work-Holding

Supplies

Service

Customer Support

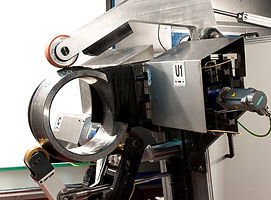

Gardner Surface Grinders

To achieve a repeatable finish, you need a robust machine. That is why our surface grinding machines are engineered to ensure exceptional stiffness, for a perfect quality grind on the first pass. All of our machines are engineered for minimum cycle time and maximum uptime - up to 98%.

Choose from horizontal double disc grinders, vertical double disc grinders or one of our single disc grinding solutions.

Horizontal Double Disc

HDD 610 / 760 / 915 / 1067

With up to 98% uptime, our Horizontal Double Disc (HDD) machines provide a robust solution for both flat and parallel surface grinding applications. Highly efficient, with exceptional stiffness and flexibility, these machines are an engineered, turnkey solution for your grinding needs.

Vertical Double Disc

VDD 305 / 355 / 455 / 510 / 585 / 760

Our vertical double disc grinding machine comes in multiple size ranges, allowing a diverse range of grinding applications. These machines are highly efficient surface grinders with repeatable high quality.

Vertical Single Disc

Vertical Single Disc

The machines’ cast iron structure ensures excellent stiffness, for high precision and high stock removal. Our vertical single disc machines are ideal for flat surface grinding of gears, rotors and other workpieces that require precise squareness.

Our VSD grinders can also be equipped with multi-component clamping, to further reduce cycle time and optimize productivity.